Novelstabilizers for long-term stabilization of polyolefins.

Processing stabilizer, polymer stabilizer, green chemistry

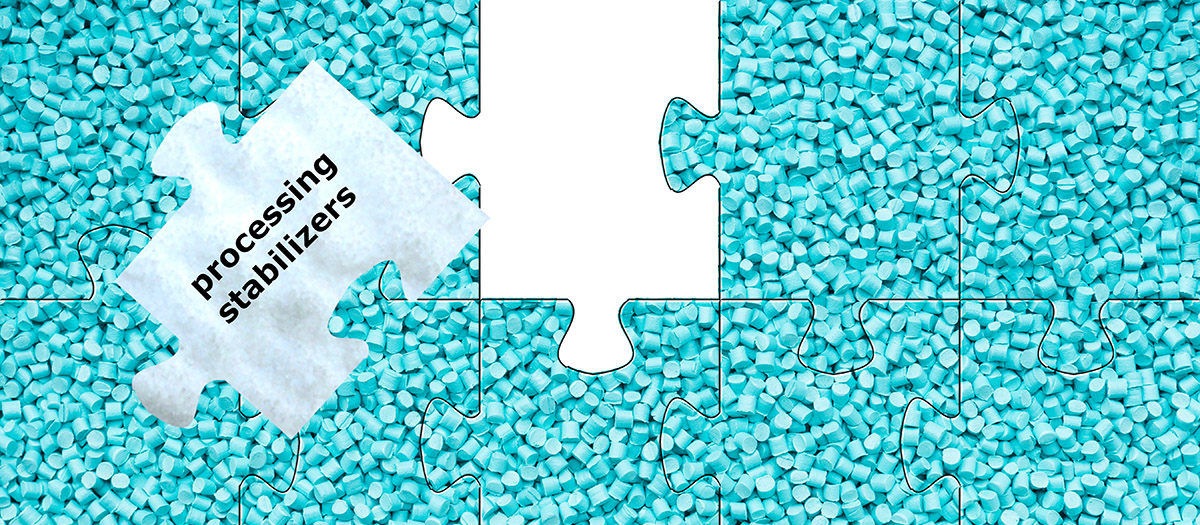

Plastics are exposed to high temperatures and mechanical stresses during processing. Without additives, this leads to the degradation of the material and loss of mechanical properties. Scientists at Fraunhofer LBF have developed new bio-based processing stabilizers that can be prepared through simple synthesis methods. They exhibit excellent process stabilizing effects on polyolefins and could replace industrially established petroleum-based stabilizers. In addition, the new antioxidants exhibit low volatility and show no degradation products that are harmful to humans. They are therefore particularly suitable for applications in food processing or pharmaceutical technology.

Sustainable antioxidants with excellent processing stability

Current topics, such as environmental compatibility, green chemicals and toxicity-releasing degradation products do not only attract attention in the production of polymers. The goal of Fraunhofer LBF is to develop new processing stabilizers based on renewable raw materials that are harmless to humans and nature and are thus particularly future-proof. In addition to high efficiency, good storage stability and high thermal stability, demands on the new stabilizers also include simple and inexpensive methods of synthesis. The synthesis of high-molecular-weight polymeric stabilizer systems makes it possible to obtain compounds with low migration tendency. This yields compounds that are harmless to humans, which can be used in the future according to REACH (Registration, Evaluation, Authorization and Restriction of Chemicals – European chemicals regulation for the risk assessment of chemical substances).

The scientists at Fraunhofer LBF have extensive expertise in additive systems and stabilizer syntheses, which has enabled them to develop a broad spectrum of new and highly efficient stabilizers in the field of heat stabilizers and flame retardants. This project facilitated the first experiments in the field of processing stabilizers. Using phosphorus-based stabilizers, a number of highly active stabilizers were formed within a short time, which are significantly more effective than industrial stabilizers with comparable storage stability. The thermal stability of the compounds is further optimized, which allows the compounds to be used in other polymer systems.

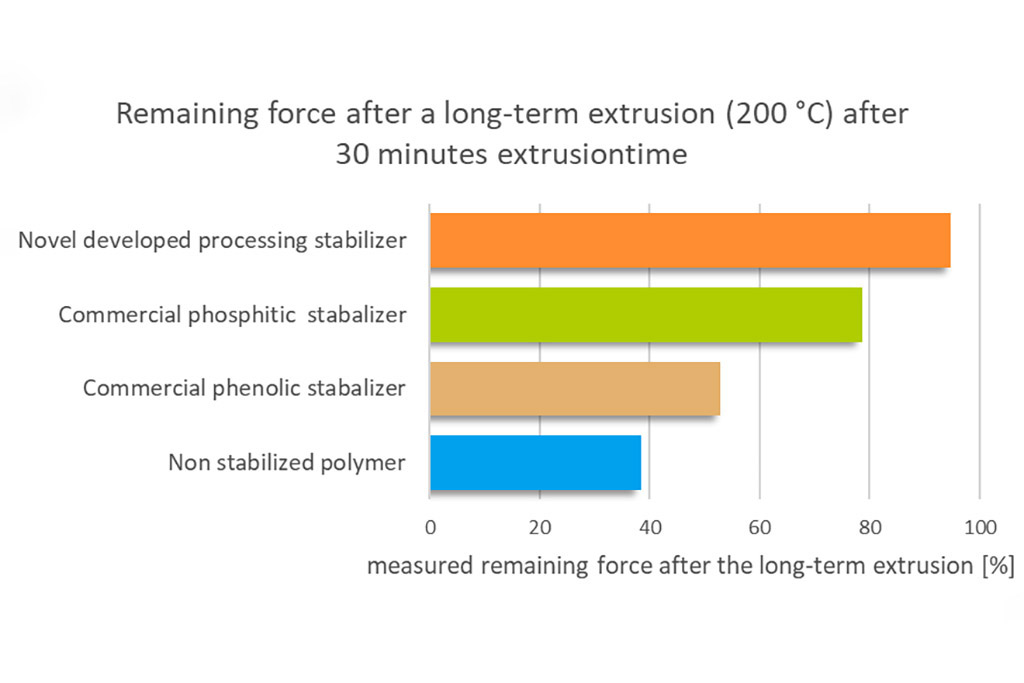

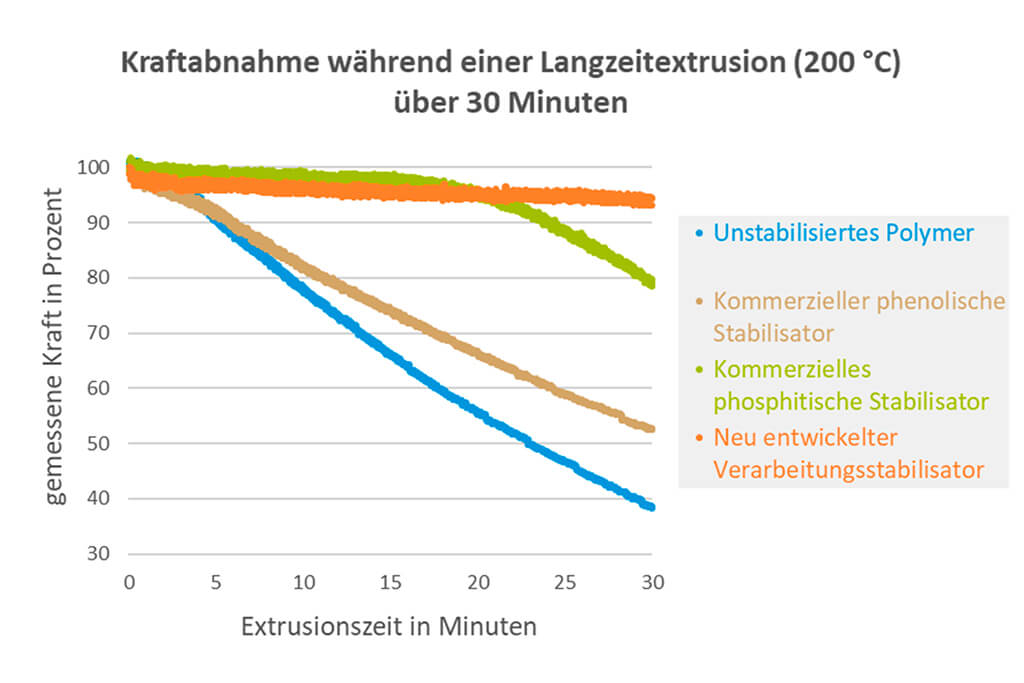

To assess the effectiveness of the new stabilizers, a long-term extrusion is currently being performed, during which the viscosity change of the polymer mass can be tracked. This way, statements about the effectiveness of the compound and conclusions about synergistic effects can be made quickly with already established systems. Other suitable processes for evaluating the effectiveness of the stabilizers are the determination of the elongation fracture point, the melt flow rate as well as the discoloration of the material.

Customer benefits

Newly developed antioxidants make it possible to preserve the physical and mechanical properties during polyolefin processing despite high impact on the material. The focus here is on replacing industrially established stabilizers. The use of non-hazardous and renewable raw materials and the low migration tendency of the compounds make these stabilizers particularly suitable for applications in which no harmful substances can be released, for example, in food technology or in pharmaceutical products.

In the field of polymer technology, Fraunhofer LBF offers the entire range from conception and implementation to the finished end product.

The research work takes place within the framework of a Fraunhofer Society vocation project and boosts the institute's competence in method development for the synthesis and accelerated evaluation of stabilizers.

Contact

- Dr. Elke Metzsch-Zilligen

- Phone: +49 6151 705-8609

- elke.metzsch-zilligen@lbf.fraunhofer.de