New methods in ultra-lightweight plastics.

QUALITATIVE ANALYSIS, LIQUID CHROMATOGRAPHY, ULTRA-LIGHTWEIGHT CONSTRUCTION

Many applications for plastics in an ultra-lightweight construction are only made possible through the use of additives, which enable the property profile of plastics to be customized for the desired application. For example, in many cases plastics need to be protected against the harmful influence of atmospheric oxygen, light or aggressive media. Fraunhofer LBF develops methods that mean even lightweight products – like car parts, packaging or components – can achieve their intended purpose with reliability.

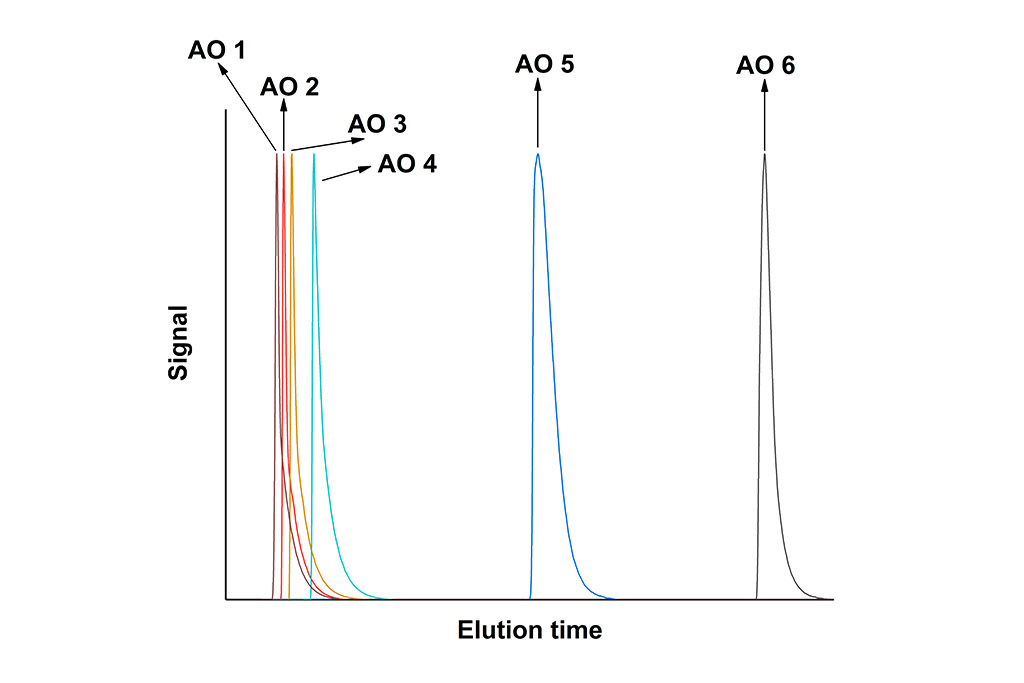

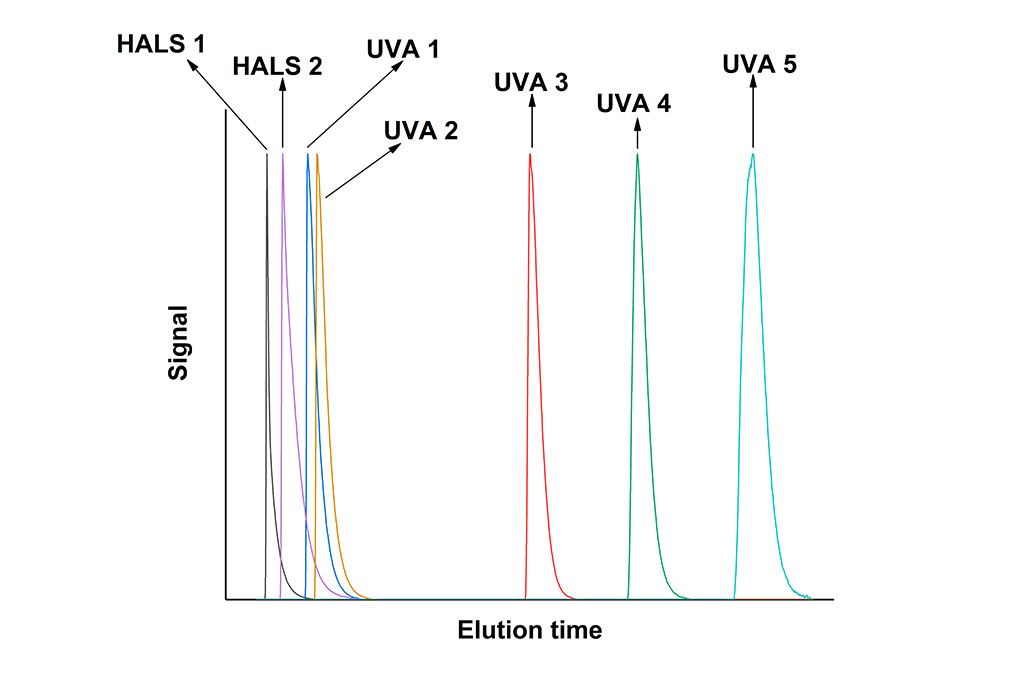

Antioxidants protect the polymer against thermo-oxidative degradation during processing and application. Another class of widely used additives are UV absorbers and hindered amine light stabilizers (HALS), which protect plastics against the harmful influence of UV radiation. One requirement that is the same for all stabilizing additives is that they must perform their function over a long period. It is therefore essential that they are held efficiently in the component under application conditions. Against this background, new stabilizers are constantly being developed with the aim of reducing their migration capacity.

Verifying structurally similar additives separately and quantitatively

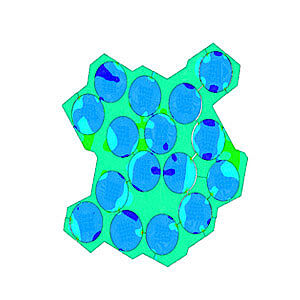

Alongside the developments in the field of additives, the requirements placed on the analytical methods for characterizing them are also sharpening. As the requirements for plastics in ultra-lightweight construction become tougher, it is increasingly the case that the desired property profile can only be achieved through a combination of different additives, so it is necessary to verify structurally similar additives separately and quantitatively. Chromatography is a very appropriate method for separating mixtures of substances. While gas chromatography has been proven to work with volatile additives, high-performance liquid chromatography (HPLC) is a highly efficient method for separating analytes with a higher molecular weight. In HPLC, a solution of analytes is fed through a stationary phase (chromatographic column), with which the individual additives interact at different intensities.

Porous graphite as the solution

Until now, HPLC methods have generally used silica gel or modified silica gel as the stationary phase and fail when modern additives are used, due to the intense interaction between additive and column material. An alternative in this case is the use of porous graphite (PGC) as the stationary phase.

While PGC has been used for many years in the analysis of active substances, its potential for separating additives has remained completely unexplored. Tests have now shown that issues that were previously unresolved in the separation and identification of additives can now be tackled with PGC as the stationary phase.

Acknowledgments

The project was funded by the German Federation of Industrial Research Associations, ”Otto von Guericke” e.V. (AiF), project no. 19826 N.

Contact

- Dr. Robert Brüll

- Phone: +49 6151 705-8639

- robert.bruell@lbf.fraunhofer.de