Optimization of scalaBle rEaltime modeLs and functIonal testing for e-drive ConceptS (OBELICS).

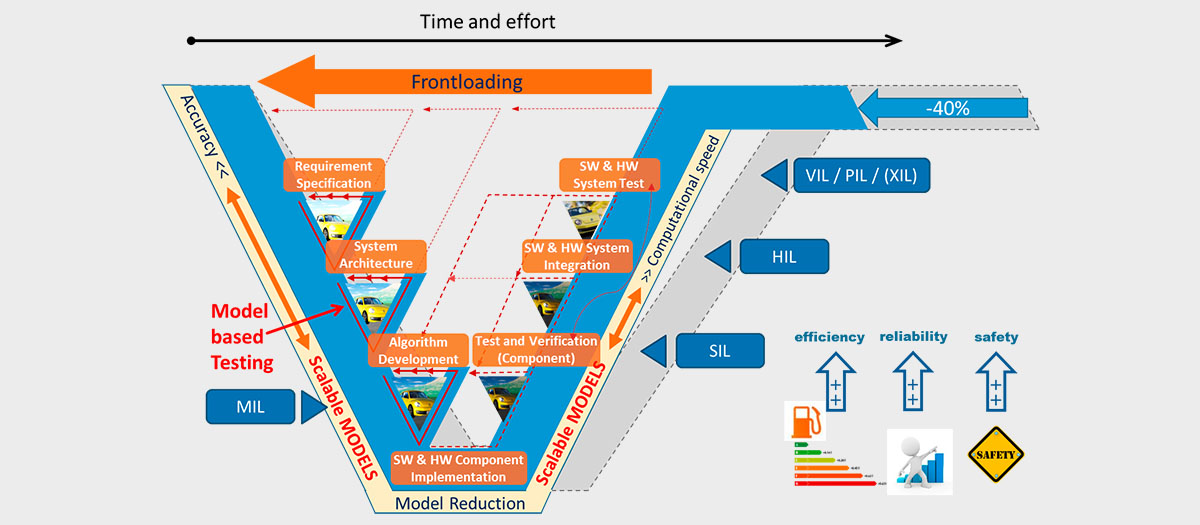

The EU-Project OBELICS follows the main goal of developing a systematic and comprehensive framework for the design, development and testing of advanced e-powertrains and electric vehicle (EV) line-ups. Using advanced heterogeneous model-based testing methods and tools, as well as scalable and easy to parameterize real-time models, OBELICS delivers reduction in development and testing efforts for electric (e-)drivetrains by 40 percent, improving efficiency of the e-drivetrain by 20 percent, improving safety of electrified vehicles by a factor of 10. Within that framework, Fraunhofer LBF is responsible for the safety assessment and testing of the power train components Battery and Inverter.

Within OBELICS, testing efforts will be transferred from the right arm of the V-model (Fig. 1) to the left in order to reduce the overall development time and effort. Since very detailed models with high accuracy are often slow in computational speed, it is important to reduce the model complexity for simulation or testing tasks in an easy and efficient way, especially when higher computational speed is required (e.g. real-time capability). Fraunhofer LBF is involved in the OBELICS project mainly in reliability and functional safety assessment of the power train and its components. By doing so, LBF will, on the one hand, gain experience in real word application of the methods and, on the other hand, will be enabled to broaden the portfolio for bilateral industry projects as a “all in all” solution from experimental, numerical, and qualitative evaluation methods.

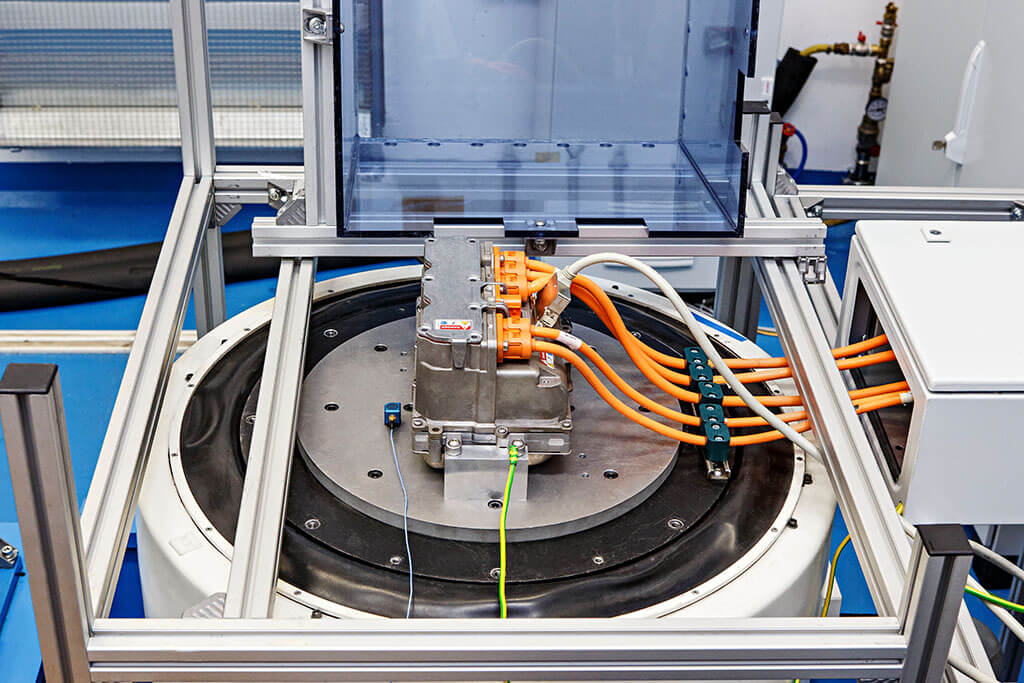

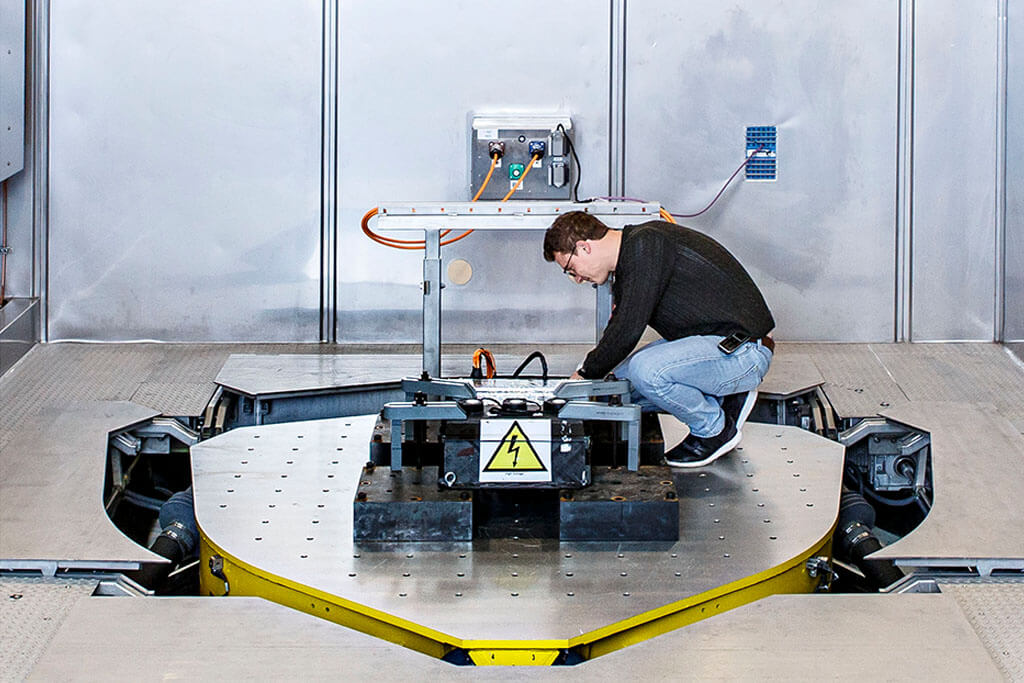

Experimental testing of batteries and inverters

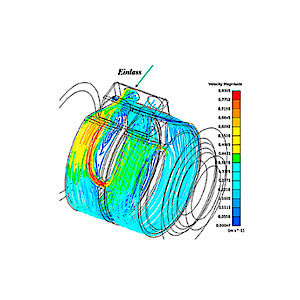

At Fraunhofer LBF, several multiphysical test stands are available, especially for testing of high voltage (HV) traction batteries (Fig. 2) and power electronics (Fig. 3). In both cases, the unique feature of these test stands is the simultaneous instead of the sequential complete operational loading like mechanical vibrations, electrical operation and resulting thermomechanical stress, and climatic conditions. Concerning the battery, a test plan was derived, as well as the positioning plan for acceleration sensors and strain gauges at the interior of the battery. The aim is to conduct mechanical tests on the test stand under different electrical load conditions while simultaneously determine the mechanical transfer function of battery packs. The inverter, on the other hand, provides the necessary input data for the modelling for the partners in other work packages.

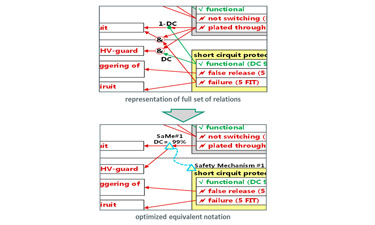

Probabilistic FMEA

Within OBELICS, the novel so-called probabilistic FMEA, currently developed by Fraunhofer LBF, will be applied to a complete power train for the first time, Fig. 4. By doing so, LBF combines all competencies in the different power train domains in one tool. As a special feature, this tool will not only be capable of calculating quantitative failure probabilities at a system or subsystem level, it also ensures the evaluation of diagnosis functions that is developed and assessed in OBELICS. Fraunhofer LBF therefore is the key partner in the safety and reliability assessment of the entire power train. In OBELICS, there is a unique chance to merge these different competencies by applying them to different real hardware like the power train’s batteries and inverters as well as a complete real vehicle provided by the project partners.

Sponsors and partners

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 769506.

Contact

- Dr. Jürgen Nuffer

- Phone: +49 6151 705 281

- jürgen.nuffer@lbf.fraunhofer.de