Efficient, parametric digital twins.

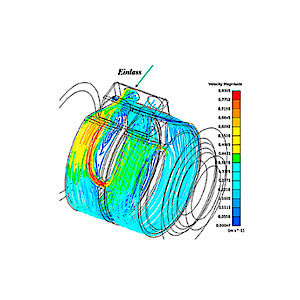

Numerical tools are indispensable for the virtual development and optimization of lightweight structures. Parametric models can speed up and simplify the development of lightweight, cost-effective structures. Efficient models can also be used for system-level simulations and together with vibration technology measures to optimize weight and NVH (Noise Vibration Harshness) behavior.

Our motivation

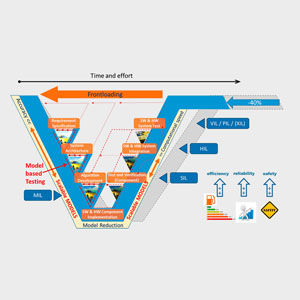

Digital twins are numerical models of the physical world that simultaneously process real and virtual information. The merging of calculated and measured signals enables a more detailed and expanded analysis of technical systems. Parametric, real-time digital twins also provide opportunities for further interesting application scenarios. The models can be quickly and efficiently validated and used for condition monitoring or as virtual sensors.

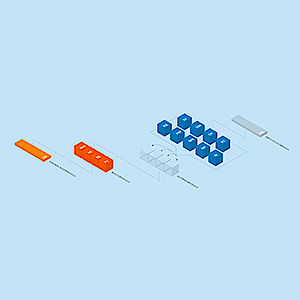

Parametric models

Scientists at Fraunhofer LBF are researching the modeling of parametric digital twins with real-time capability. Mechanical structures are described in detail by using finite element models. They are furthermore simplified through parametric model order reduction processes allowing them to be solved within the time domain or in real time. Thus, the effects of modifications, such as the variation of weight or material properties, on the overall system can be calculated for a variety of operating conditions. Along with vibration technology measures (e.g. vibration absorbers, isolation, active engine mounts), the material properties of components can be optimized in terms of lightweight construction, NVH and costs. This also facilitates the definition of nonlinear material properties through the parametric description of the reduced-order models.

Additional application scenarios arise for this type of models within the context of digitalization. For example, analysis of components and systems in design and optimization processes can be executed more efficiently. The specific focus is on feasibility and sensitivity analyses, design space explorations and parameter studies in hardware-in-the-loop experiments (e.g. variation of the virtual subsystem). The numerical models generated in the development phases can also be used in operational processes for condition monitoring and control. During monitoring, the values derived from the model calculations are used as virtual sensors or for automated online model update.

Your efficient product development

Thanks to Fraunhofer LBF’s expertise in the development and application of modern methods of numerical system simulation and vibration technology system optimization, components and systems can be analyzed and optimized throughout the entire product development, from the concept to the test phase. Challenging tasks along the product development process can be holistically investigated in a targeted manner, facilitating solutions for products with customized dynamic properties.

The work was carried out as part of the EU ”Horizon 2020” project ALLIANCE (#723893).

Contact

- Dipl.-Ing. Christoph Tamm

- Phone: +49 6151 705-8431

- christoph.tamm@lbf.fraunhofer.de